Aged Coffee

Coffee stored in a warehouse for up to several years to reduce acidity and increase body. When stored properly, aged coffees have an unusual and almost musty, but pleasant, taste.

|

Beneficio

A coffee mill where harvested cherries are processed and sorted before final bagging for export. Beneficio means benefit, or profit, in Spanish. Traditionally, a Beneficio was the local mill where farmers brought ripe cherries for processing. Increasingly, farmers are installing their own mills, or Beneficios.

|

Coffee Berry Borer

The Coffee Berry Borer (CBB), or Hypthenemus Hampei, is one of the most significant pest problems for coffee farmers. An adult CBB is a black, two millimeter long, beetle that bores holes through the seeds coffee cherries. "Broca" is the widely used Spanish term for the coffee berry borer.

Video

|

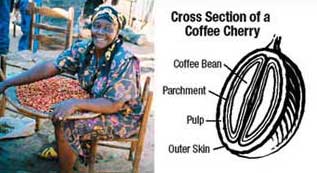

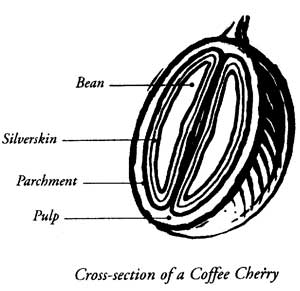

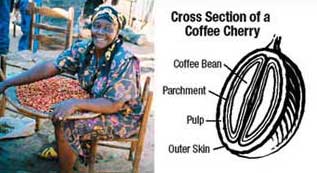

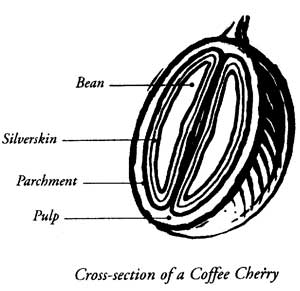

Coffee Cherry

Coffee beans start out as ripe coffee cherries which are harvested and processed various ways to remove the skin, pulp, and parchment. The dried parchment of coffee cherry seeds are removed to expose the two (sometimes one) "coffee beans". If properly stored, unroasted coffee beans can stay alive for months, and may even germinate into new Coffee plants if planted and watered.

|

Coffee Leaf Rust

Coffee Leaf Rust (CLR) became a problem for coffee farmers in Sri Lanka in the 1860s. CLR has since spread to every coffee growing region of the world, and it destroyed Brazil's crop in 1970 as it did previously on the Islands of Java and Sri Lanka nearly a century before. Many affected plantations replaced their Arabica trees with more disease resistant Robusta. Some affected coffee producing countries have since began replacing the now less desirable Robusta trees with newer Arabica cultivars that are more disease resistant compared to the "heirloom" classics Typica and Bourbon. CLR is often prevented by the use of copper-based fungicides.

|

Dry Process

In the dry process, ripe cherries are first dried in the sun, after which the dried skin, pulp, and parchment are removed from the bean (seed). The process takes about two weeks and the cherries must be raked while drying to avoid mildew. Dry processing produces coffees with less acidity and more body compared to the wet process. Dry processing is only done in growing regions with a naturally hot and dry climate. Brazil, Ethiopia, and Yemen produce most of the worlds dry processed coffees. Dry processed coffee is also called "unwashed", or "natural".

|

Estate

A coffee estate is a coffee plantation. Estate coffees typically sell at a premium due to better consistency and higher quality control compared to coffees collected from many small farms.

|

Fazenda

Portuguese for "farm". Coffee plantations in Brazil, for example, are called Fazendas.

|

Floaters

Coffee cherries that float in water and are 'floated-off' during wet-processing. Overripe, dried, damaged, or deformed coffee cherries tend to float and are discarded at the beginning of wet processing. Also called "lights".

|

Harvest Machine

Coffee harvest machines are used mostly on flat plantations at lower elevations. Robusta is harvested mostly by machine, while Arabica, which is normally grown at higher elevations, is typically picked by hand.

Video

|

Harvesting

Coffee harvesting is done mostly by hand at higher elevations, and by machine if possible at lower elevations. For better taste results, only ripe cherries are harvested. Harvesting by machine is difficult on steep terrain, so mountain grown coffees are almost always harvested by hand.

|

Hulling

Removing the parchment, or hull, that surrounds the coffee beans in a coffee cherry.

|

KVW

Kaffee Veredelungs Werk. KVW is a German company that, among other things, decaffeinates coffee beans. KVW decaffeinates large quantities of coffee beans, including the Methylene Chloride (MC) solvent method. Using the MC method, the coffee beans are heated with steam and exposed to Methylene Chloride which removes the caffeine but not the flavor. The resulting Methylene Chloride and Caffeine mixture is then separated from the coffee. KVW MC decaffeinated coffee has been thoroughly investigated and determined safe by the United States Food and Drug Administration (FDA). Methylene Chloride boils at 104 degrees Fahrenheit, so any traces solvent that could inadvertantly be left in the beans would be boiled away during roasting. Final roasted bean temperature is above 400 degrees Fahrenheit.

|

Methyl Chloride

A solvent commonly used to decaffeinate coffee. To make decaffeinated coffee, unroasted beans may be heated with steam and exposed to Methylene Chloride. The resulting Methylene Chloride and Caffeine mixture is completely removed from the coffee. Since Methylene Chloride boils at 104 degrees Fahrenheit, any traces of solvent left in the beans would be boiled away during roasting, as the beans reach temperatures above 400 degrees Fahrenheit.

|

Monsooned

Coffee deliberately exposed to moisture-laden monsoon winds in an open warehouse for about one year. Monsooning is done to recreate the flavor of coffees once transferred by slow sailing wooden ships from India to Europe around the Cape of Good Hope.

|

Outer Skin

The thick outermost membrane of the coffee cherry (fruit), similar to the skin of a grape. In the wet, and semi-dry processes, the skin of ripe coffee cherries is removed before drying the coffee beans. In the dry process, the skin is left in place while the whole ripe coffee cherries are dried to allow easier separation of the skin, pulp and hull from the coffee beans.

|

Parchment

Parchment Skin is the hull of a coffee cherry seed that surrounds the "coffee bean". The parchment skin is removed from the coffee bean during processing. The silver skin usually remains until it floats away, burns away, or is otherwise separated as "chaff" during the roasting process.

|

Parchment Coffee

Coffee beans with the skin and pulp removed, but with the parchment (hull) still attached. Dried parchments are transferred to hulling facilities where the hulls are removed and the beans are packaged in large burlap bags ready for export.

|

Processed Coffee

Unroasted coffee beans that have been sorted, pulped, dried, and separated from the hull.

|

Pulp

The mucilage between the coffee cherry skin and the pit (coffee beans). Coffee cherry pulp has a texture similar to a grapes and is normally dried or fermented to allow easier separation from the coffee beans.

|

Pulping

Removing the pulp as part of the wet process. After picking coffee cherries, the first step of processing, using the wet method, is to remove the skin and pulp. Conventional pulping machines have a rotating cylinder that collects harvested cherries immersed in water and presses them against perforations just large enough for the beans to pass. The beans of soft cherries are pushed through the perforations and collected separately while the harder green cherries along with the skin and much of the pulp from the ripe cherries are passed through the machine.

|

Ripe Coffee

Only ripe coffee cherries should be harvested for processing. Ripe cherries are plump and depending on variety have a red or yellow color. Under-ripe cherries are hard and green. Over-ripe cherries have a dark and shriveled appearance. Ripe cherries are separated from under-ripe and over-ripe cherries by hand picking and by machine during processing.

|

Semi Dry Process

In the semi dry process, coffee beans are pulped as in the wet process. The coffee beans with parchment and some mucilage still attached are then dried instead of the usual fermentation done in the wet process. After drying, the coffee beans are dehulled (separated from the parchment), sorted, and placed in burlap sacks for export. The semi-dry process is common in the islands of Sumatra and Sulawesi, and is sometimes used in Brazil.

|

Silver Skin

The thin membrane, similar to rice paper, that adheres to coffee beans after removing the husk (hull). Processing may "polish" the unroasted coffee beans removing much of the silver skin. Any remaining silver skin is removed during the roasting process.

|

Sorting

Processed coffees are sometimes hand sorted to remove defects or to separate by grade.

|

Swiss Water Process

The SWISS WATERŪ Process is a 100% chemical free coffee decaffeination process. Most decaffeination processes use chemical solvents, such as methylene chloride (MC). The SWISS WATERŪ Process uses only water to remove caffeine, producing a water processed decaf coffee.

|

Wet Mill

Equipment for processing harvested coffee cherries by the wet method.

|

Wet Process

In the wet process, ripe cherries are first immersed in water where any floating cherries are removed as defective. The remaining cherries are then pressed by machine against a perforated surface, allowing only the seed, and some attached pulp, to pass through the holes. The remaining pulp is then removed by placing the beans into a fermentation tank to loosen the pulp before washing the pulp away with water. After the pulp is removed, the coffee beans are then dried to about ten to twelve percent moisture content, usually by a combination of sun drying and machine drying. Machine drying is common practice, especially in damp climates, to prevent mildew. Wet processed coffee is sometimes called washed coffee, in reference to the washing done to separate the pulp from the beans. Also called the wet method.

Video

|

The Coffee Berry Borer (CBB), or Hypthenemus Hampei, is one of the most significant pest problems for coffee farmers. An adult CBB is a black, two millimeter long, beetle that bores holes through the seeds coffee cherries. "Broca" is the widely used Spanish term for the coffee berry borer.

The Coffee Berry Borer (CBB), or Hypthenemus Hampei, is one of the most significant pest problems for coffee farmers. An adult CBB is a black, two millimeter long, beetle that bores holes through the seeds coffee cherries. "Broca" is the widely used Spanish term for the coffee berry borer.

Coffee beans start out as ripe coffee cherries which are harvested and processed various ways to remove the skin, pulp, and parchment. The dried parchment of coffee cherry seeds are removed to expose the two (sometimes one) "coffee beans". If properly stored, unroasted coffee beans can stay alive for months, and may even germinate into new Coffee plants if planted and watered.

Coffee beans start out as ripe coffee cherries which are harvested and processed various ways to remove the skin, pulp, and parchment. The dried parchment of coffee cherry seeds are removed to expose the two (sometimes one) "coffee beans". If properly stored, unroasted coffee beans can stay alive for months, and may even germinate into new Coffee plants if planted and watered.

Coffee Leaf Rust (CLR) became a problem for coffee farmers in Sri Lanka in the 1860s. CLR has since spread to every coffee growing region of the world, and it destroyed Brazil's crop in 1970 as it did previously on the Islands of Java and Sri Lanka nearly a century before. Many affected plantations replaced their Arabica trees with more disease resistant Robusta. Some affected coffee producing countries have since began replacing the now less desirable Robusta trees with newer Arabica cultivars that are more disease resistant compared to the "heirloom" classics Typica and Bourbon. CLR is often prevented by the use of copper-based fungicides.

Coffee Leaf Rust (CLR) became a problem for coffee farmers in Sri Lanka in the 1860s. CLR has since spread to every coffee growing region of the world, and it destroyed Brazil's crop in 1970 as it did previously on the Islands of Java and Sri Lanka nearly a century before. Many affected plantations replaced their Arabica trees with more disease resistant Robusta. Some affected coffee producing countries have since began replacing the now less desirable Robusta trees with newer Arabica cultivars that are more disease resistant compared to the "heirloom" classics Typica and Bourbon. CLR is often prevented by the use of copper-based fungicides.

A coffee estate is a coffee plantation. Estate coffees typically sell at a premium due to better consistency and higher quality control compared to coffees collected from many small farms.

A coffee estate is a coffee plantation. Estate coffees typically sell at a premium due to better consistency and higher quality control compared to coffees collected from many small farms.

Portuguese for "farm". Coffee plantations in Brazil, for example, are called Fazendas.

Portuguese for "farm". Coffee plantations in Brazil, for example, are called Fazendas.

Coffee harvest machines are used mostly on flat plantations at lower elevations. Robusta is harvested mostly by machine, while Arabica, which is normally grown at higher elevations, is typically picked by hand.

Coffee harvest machines are used mostly on flat plantations at lower elevations. Robusta is harvested mostly by machine, while Arabica, which is normally grown at higher elevations, is typically picked by hand.

Coffee harvesting is done mostly by hand at higher elevations, and by machine if possible at lower elevations. For better taste results, only ripe cherries are harvested. Harvesting by machine is difficult on steep terrain, so mountain grown coffees are almost always harvested by hand.

Coffee harvesting is done mostly by hand at higher elevations, and by machine if possible at lower elevations. For better taste results, only ripe cherries are harvested. Harvesting by machine is difficult on steep terrain, so mountain grown coffees are almost always harvested by hand.

Kaffee Veredelungs Werk. KVW is a German company that, among other things, decaffeinates coffee beans. KVW decaffeinates large quantities of coffee beans, including the Methylene Chloride (MC) solvent method. Using the MC method, the coffee beans are heated with steam and exposed to Methylene Chloride which removes the caffeine but not the flavor. The resulting Methylene Chloride and Caffeine mixture is then separated from the coffee. KVW MC decaffeinated coffee has been thoroughly investigated and determined safe by the United States Food and Drug Administration (FDA). Methylene Chloride boils at 104 degrees Fahrenheit, so any traces solvent that could inadvertantly be left in the beans would be boiled away during roasting. Final roasted bean temperature is above 400 degrees Fahrenheit.

Kaffee Veredelungs Werk. KVW is a German company that, among other things, decaffeinates coffee beans. KVW decaffeinates large quantities of coffee beans, including the Methylene Chloride (MC) solvent method. Using the MC method, the coffee beans are heated with steam and exposed to Methylene Chloride which removes the caffeine but not the flavor. The resulting Methylene Chloride and Caffeine mixture is then separated from the coffee. KVW MC decaffeinated coffee has been thoroughly investigated and determined safe by the United States Food and Drug Administration (FDA). Methylene Chloride boils at 104 degrees Fahrenheit, so any traces solvent that could inadvertantly be left in the beans would be boiled away during roasting. Final roasted bean temperature is above 400 degrees Fahrenheit.

Coffee deliberately exposed to moisture-laden monsoon winds in an open warehouse for about one year. Monsooning is done to recreate the flavor of coffees once transferred by slow sailing wooden ships from India to Europe around the Cape of Good Hope.

Coffee deliberately exposed to moisture-laden monsoon winds in an open warehouse for about one year. Monsooning is done to recreate the flavor of coffees once transferred by slow sailing wooden ships from India to Europe around the Cape of Good Hope.

The thick outermost membrane of the coffee cherry (fruit), similar to the skin of a grape. In the wet, and semi-dry processes, the skin of ripe coffee cherries is removed before drying the coffee beans. In the dry process, the skin is left in place while the whole ripe coffee cherries are dried to allow easier separation of the skin, pulp and hull from the coffee beans.

The thick outermost membrane of the coffee cherry (fruit), similar to the skin of a grape. In the wet, and semi-dry processes, the skin of ripe coffee cherries is removed before drying the coffee beans. In the dry process, the skin is left in place while the whole ripe coffee cherries are dried to allow easier separation of the skin, pulp and hull from the coffee beans.

Parchment Skin is the hull of a coffee cherry seed that surrounds the "coffee bean". The parchment skin is removed from the coffee bean during processing. The silver skin usually remains until it floats away, burns away, or is otherwise separated as "chaff" during the roasting process.

Parchment Skin is the hull of a coffee cherry seed that surrounds the "coffee bean". The parchment skin is removed from the coffee bean during processing. The silver skin usually remains until it floats away, burns away, or is otherwise separated as "chaff" during the roasting process.

Removing the pulp as part of the wet process. After picking coffee cherries, the first step of processing, using the wet method, is to remove the skin and pulp. Conventional pulping machines have a rotating cylinder that collects harvested cherries immersed in water and presses them against perforations just large enough for the beans to pass. The beans of soft cherries are pushed through the perforations and collected separately while the harder green cherries along with the skin and much of the pulp from the ripe cherries are passed through the machine.

Removing the pulp as part of the wet process. After picking coffee cherries, the first step of processing, using the wet method, is to remove the skin and pulp. Conventional pulping machines have a rotating cylinder that collects harvested cherries immersed in water and presses them against perforations just large enough for the beans to pass. The beans of soft cherries are pushed through the perforations and collected separately while the harder green cherries along with the skin and much of the pulp from the ripe cherries are passed through the machine.

Only ripe coffee cherries should be harvested for processing. Ripe cherries are plump and depending on variety have a red or yellow color. Under-ripe cherries are hard and green. Over-ripe cherries have a dark and shriveled appearance. Ripe cherries are separated from under-ripe and over-ripe cherries by hand picking and by machine during processing.

Only ripe coffee cherries should be harvested for processing. Ripe cherries are plump and depending on variety have a red or yellow color. Under-ripe cherries are hard and green. Over-ripe cherries have a dark and shriveled appearance. Ripe cherries are separated from under-ripe and over-ripe cherries by hand picking and by machine during processing.

Processed coffees are sometimes hand sorted to remove defects or to separate by grade.

Processed coffees are sometimes hand sorted to remove defects or to separate by grade.

The SWISS WATERŪ Process is a 100% chemical free coffee decaffeination process. Most decaffeination processes use chemical solvents, such as methylene chloride (MC). The SWISS WATERŪ Process uses only water to remove caffeine, producing a water processed decaf coffee.

The SWISS WATERŪ Process is a 100% chemical free coffee decaffeination process. Most decaffeination processes use chemical solvents, such as methylene chloride (MC). The SWISS WATERŪ Process uses only water to remove caffeine, producing a water processed decaf coffee.

Equipment for processing harvested coffee cherries by the wet method.

Equipment for processing harvested coffee cherries by the wet method.